Taking Action

Environmental impact

*Compared with 2021 baseline

**Scope 1 and 2 under the Greenhouse Gas Protocol. For more information, please refer to www.ghgprotocol.org

Our measures helped bring down emissions from our own operations** by 11% in 2023 despite continued growth in our network of stores and distribution centres, putting us on course to meet our 2030 target.

We acknowledge that our business – like other businesses – impacts the environment. Some of this comes from the energy we use at our stores, offices and distribution centres. By 2030, we want to reduce carbon emissions from our own operations by at least 60%.* We are doing this by reducing our energy intensity, switching where possible to biodiesel for Action trucks and buying more renewable electricity.

We’re reducing carbon emissions from our own operations

Energy and emissions

We are committed to reducing carbon emissions at our own operations and supply chain in line with SBTi target-setting criteria.

In 2023, we reduced carbon emissions from our own operations by 11%.

We have now installed solar panels at seven Action distribution centres across Europe, part of our plan to use more renewable energy and reduce our carbon footprint. In 2023, electricity produced by these panels equated to 63% of our centres’ total energy use. By the end of the year, 74 of our stores had access to solar panels.

All new stores opened in 2023 operate without gas, which meant in total, we finished the year with 88% of stores operating without a gas supply. Across the year, we also disconnected 300 Action stores from the main gas supply – meaning we have just 63 more stores to disconnect in 2024 to reach our aim of all stores operating without gas.

During 2023, we extended the use of LED lighting to 99.8% of our stores, installed more solar panels and introduced new smart meters, which allow us to keep a close track of energy consumption.

The first of our fully electric trucks were commissioned in February. These trucks boast a 540 kWh battery and have a range of more than 200km. They’ll operate out of our distribution centres at Echt and Biblis. The trucks are part of a trial to learn more about electric transport – and determine to what extent we’re able to use electric vehicles in our logistics.

We increased our use of cleaner, renewable energy. Around 90% of electricity for our stores now comes from green sources. During the year, we also began using biodiesel in 150 Action-owned trucks and piloted four new zero-emission e-trucks at distribution centres in the Netherlands and Germany.

These are indirect emissions resulting from the production and transportation of the products we sell in our stores. The vast majority of our carbon footprint is made up of these emissions. We have agreements in place with Maersk and Kuehne + Nagel to use eco-fuels when shipping Action products from Asia to Europe. For the first time this year, we have established a baseline calculation for our scope 3, supply chain emissions – we’ll use this calculation as a reference for future reduction initiatives.

We also want to help reduce emissions from our wider supply chain

(tonnes, CO2 equivalent, 2023)

Electricity use –market-based

Total (scope 1 and 2) 25,516

Transport from own vehicles

Refrigerant leakage

Scope 2

Scope 1

Natural gas

Goods and services we purchase

4,096,990

Total 5,493,467

End-of-life treatment of sold products 423,675

Use of products we sell to customers 556,453

Employee commuting 17,698

Business travel 583

Waste generated by our business activities 8,131

Upstream transportation of products to our stores 185,958

Fuel and energy-related activities 16,682

Capital goods, including property, equipment and machinery 187,297

Where do our scope 3 emissions come from?

According to our calculation – based on 2021 data – scope 3 emissions from our supply chain amounted to 5.5 million tonnes (CO2 equivalent), representing 99% of our total carbon footprint – common for the retail sector. Seventy-five percent of these emissions come from the products we buy, including the products’ raw materials, manufacturing and transport. These insights will be used to further develop our climate strategy and roadmap, where we will work with our suppliers and supply chain partners to reduce our emissions in the future.

(2021 baseline data)

In 2023, Action launched its first-ever circular product: plastic baskets ideal for organising pens and kitchen utensils. The baskets are a closed-loop product, made entirely from damaged items returned to Action by customers, preventing material waste. We will be looking to expand our range of recycled, closed-loop products in the near future.

Product circularity

We make our products more circular by improving material inflow, product lifespan and ease of recyclability.

In 2023, we increased our circularity score across our product range to 4.8%*.

*According to the Circular Transition Indicator (CTI), developed by the World Business Council for Sustainable Development. See Appendix for more details.

We increasingly focus on circularity when sourcing our products. This allows for waste and emission reductions. To achieve our goals, we are working end-to-end from initial product design to disposal, cooperating closely with our suppliers to increase durability, for example, or make our products easier to recycle or reuse. We are also using more recycled materials in our products (see below). To support our efforts, we are working with Circle Economy, and have partnered with the Ellen MacArthur Foundation. We have also paired up with Delft Technical University in the Netherlands to conduct research into circularity by design and help us develop a guide for buying teams.

Our products will become more circular

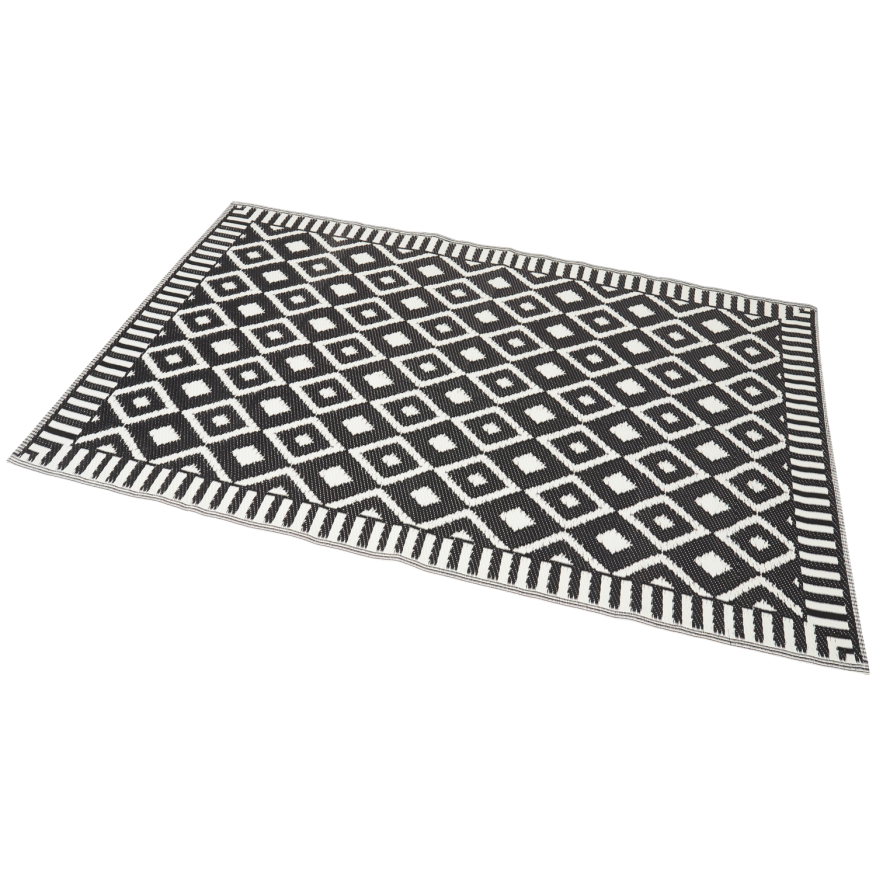

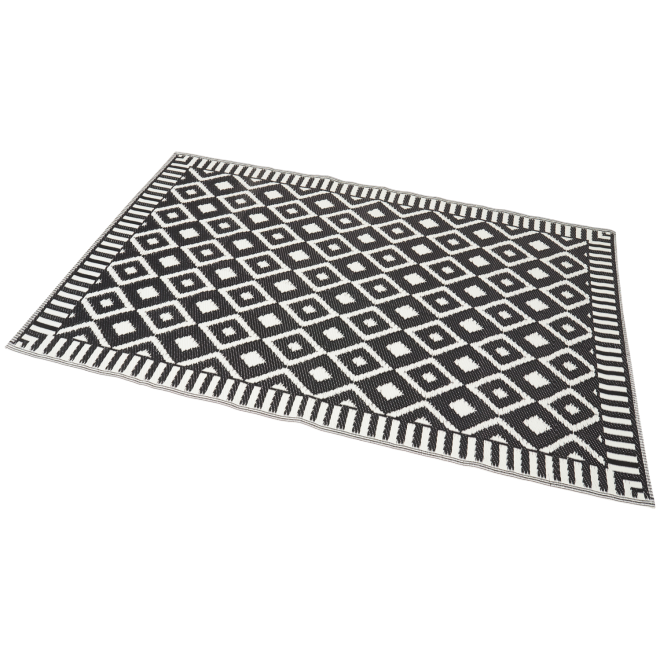

Made from 100% recycled plastic

Outdoor rug

Made from 40% recycled aluminium

Marble stone frying pan

Made using 100% recycled materials

Action carrier bag

Sustainable packaging

We are working to reduce the use of packaging materials, decrease the weight, while increasing the recyclability and recycled content.

We reduced packaging weight by 20% (compared to baseline 2019) – keeping us on track to meet our 25% reduction target by the end of 2025.

We are working to make more of our packaging recyclable. We are also increasing the use of recycled materials and changing materials where it makes sense to from a sustainability viewpoint. We have trained our buying teams on sustainable packaging, which has helped keep us on target to reach our goal of a 25% reduction in the weight of packaging for our fixed assortment by 2025.

By switching to a smaller tube for our masking tape, we managed to save around 140 tonnes a year in packaging – just one example of what we are doing to make our packaging more sustainable. In 2022, we had already eliminated black plastic and achieved our goal of making 100% of our Action-brand packaging recyclable.

Energy and emissions

We are committed to reducing carbon emissions at our own operations and supply chain in line with SBTi target-setting criteria.

In 2023, we reduced carbon emissions from our own operations by 11%.

*Compared with 2021 baseline

**Scope 1 and 2 under the Greenhouse Gas Protocol. For more information, please refer to www.ghgprotocol.org

Our measures helped bring down emissions from our own operations** by 11% in 2023 despite continued growth in our network of stores and distribution centres, putting us on course to meet our 2030 target.

We acknowledge that our business – like other businesses – impacts the environment. Some of this comes from the energy we use at our stores, offices and distribution centres. By 2030, we want to reduce carbon emissions from our own operations by at least 60%.* We are doing this by reducing our energy intensity, switching where possible to biodiesel for Action trucks and buying more renewable electricity.

We’re reducing carbon emissions from our own operations

During 2023, we extended the use of LED lighting to 99.8% of our stores, installed more solar panels and introduced new smart meters, which allow us to keep a close track of energy consumption.

The first of our fully electric trucks were commissioned in February. These trucks boast a 540 kWh battery and have a range of more than 200km. They’ll operate out of our distribution centres at Echt and Biblis. The trucks are part of a trial to learn more about electric transport – and determine to what extent we’re able to use electric vehicles in our logistics.

All new stores opened in 2023 operate without gas, which meant in total, we finished the year with 88% of stores operating without a gas supply. Across the year, we also disconnected 300 Action stores from the main gas supply – meaning we have just 63 more stores to disconnect in 2024 to reach our aim of all stores operating without gas.

We have now installed solar panels at seven Action distribution centres across Europe, part of our plan to use more renewable energy and reduce our carbon footprint. In 2023, electricity produced by these panels equated to 63% of our centres’ total energy use. By the end of the year, 74 of our stores had access to solar panels.

We also want to help reduce emissions from our wider supply chain

We increased our use of cleaner, renewable energy. Around 90% of electricity for our stores now comes from green sources. During the year, we also began using biodiesel in 150 Action-owned trucks and piloted four new zero-emission e-trucks at distribution centres in the Netherlands and Germany.

These are indirect emissions resulting from the production and transportation of the products we sell in our stores. The vast majority of our carbon footprint is made up of these emissions. We have agreements in place with Maersk and Kuehne + Nagel to use eco-fuels when shipping Action products from Asia to Europe. For the first time this year, we have established a baseline calculation for our scope 3, supply chain emissions – we’ll use this calculation as a reference for future reduction initiatives.

Electricity use –market-based

Total (scope 1 and 2) 25,516

Transport from own vehicles

Refrigerant leakage

Scope 2

Scope 1

Natural gas

(tonnes, CO2 equivalent, 2023)

End-of-life treatment of sold products 423,675

Use of products we sell to customers 556,453

Employee commuting 17,698

Business travel 583

Waste generated by our business activities 8,131

Upstream transportation of products to our stores 185,958

Fuel and energy-related activities 16,682

Capital goods, including property, equipment and machinery 187,297

Where do our scope 3 emissions come from?

According to our calculation – based on 2021 data – scope 3 emissions from our supply chain amounted to 5.5 million tonnes (CO2 equivalent), representing 99% of our total carbon footprint – common for the retail sector. Seventy-five percent of these emissions come from the products we buy, including the products’ raw materials, manufacturing and transport. These insights will be used to further develop our climate strategy and roadmap, where we will work with our suppliers and supply chain partners to reduce our emissions in the future.

(2021 baseline data)

Goods and services we purchase

4,096,990

Total 5,493,467

We increasingly focus on circularity when sourcing our products. This allows for waste and emission reductions. To achieve our goals, we are working end-to-end from initial product design to disposal, cooperating closely with our suppliers to increase durability, for example, or make our products easier to recycle or reuse. We are also using more recycled materials in our products (see below). To support our efforts, we are working with Circle Economy, and have partnered with the Ellen MacArthur Foundation. We have also paired up with Delft Technical University in the Netherlands to conduct research into circularity by design and help us develop a guide for buying teams.

Product circularity

We make our products more circular by improving material inflow, product lifespan and ease of recyclability.

In 2023, we increased our circularity score across our product range to 4.8%*.

*According to the Circular Transition Indicator (CTI), developed by the World Business Council for Sustainable Development. See Appendix for more details.

In 2023, Action launched its first-ever circular product: plastic baskets ideal for organising pens and kitchen utensils. The baskets are a closed-loop product, made entirely from damaged items returned to Action by customers, preventing material waste. We will be looking to expand our range of recycled, closed-loop products in the near future.

Our products will become more circular

Made using 100% recycled materials

Action carrier bag

Made from 40% recycled aluminium

Marble stone frying pan

Made from 100% recycled plastic

Outdoor rug

By switching to a smaller tube for our masking tape, we managed to save around 140 tonnes a year in packaging – just one example of what we are doing to make our packaging more sustainable. In 2022, we had already eliminated black plastic and achieved our goal of making 100% of our Action-brand packaging recyclable.

Sustainable packaging

We are working to reduce the use of packaging materials, decrease the weight, while increasing the recyclability and recycled content.

We reduced packaging weight by 20% (compared to baseline 2019) – keeping us on track to meet our 25% reduction target by the end of 2025.

We are working to make more of our packaging recyclable. We are also increasing the use of recycled materials and changing materials where it makes sense to from a sustainability viewpoint. We have trained our buying teams on sustainable packaging, which has helped keep us on target to reach our goal of a 25% reduction in the weight of packaging for our fixed assortment by 2025.