Back to Product

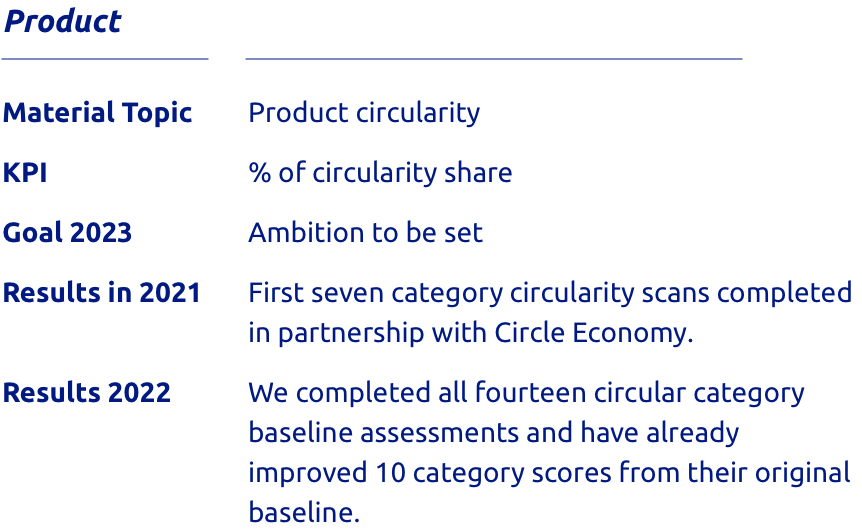

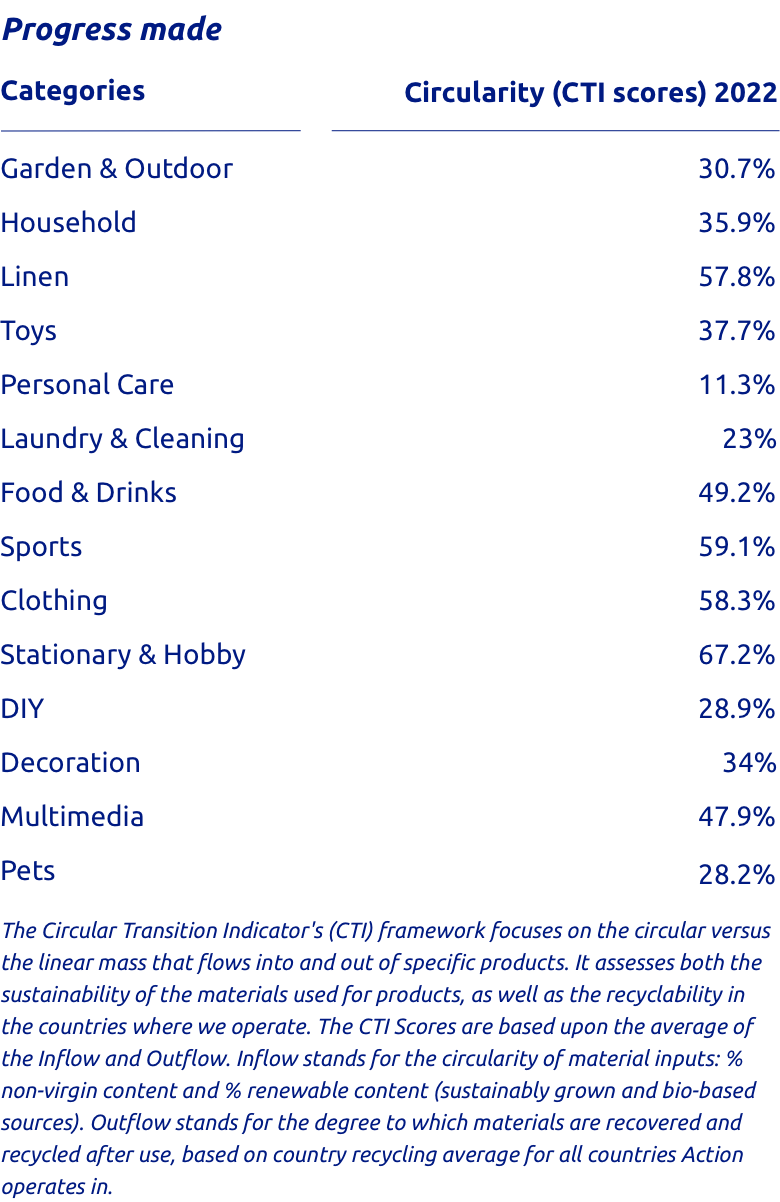

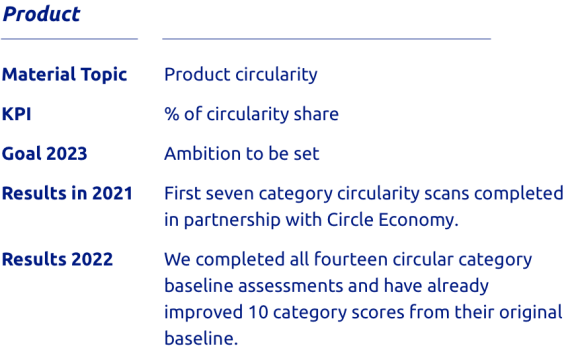

Product circularity

We have embraced the circularity philosophy because we recognise that we cannot continue to rely on finite, non-renewable resources. In this year’s materiality assessment, Product circularity was confirmed as an important material topic. Our progress is measured through the circularity percentage per product category.

Wall of fame

changed to 100% recycled polypropylene

Action shopping bag

changed to 40% recycled aluminium

Marble stone frying pans

changed to 100% recycled plastic

Outdoor carpet

Management of material topic

The responsibility for product circularity is taken seriously at Action and managed per product category. We look at the three stages of circularity: design, use and end of life. Depending on the type of product functionality, we define which circular improvements to make.

We also have special policies for unsold and damaged goods. Of course, we aim to sell as many of our products to our customers. In the case of seasonal unsold goods, we store them in our DCs for next year. In addition, we move stock from store to store, so we refill stock in one store with the surplus of another store. Items that are not sold despite our efforts or that we no longer wish to sell ourselves are sent back to our DC and sold on to other resellers.

The damaged goods that are returned to our store are carefully selected and categorised into waste or re-sellable products. Re-sellable products can find their way back to our own stores or to other markets. The waste is carefully separated. For example, food, iron, copper, plastic and electronics are collected by organisations that process it into reusable materials. Hazardous materials, such as batteries, are already collected in our stores and processed separately.

Progress made

In 2022, we completed all fourteen circular category baseline assessments and have already improved 10 categories based on the assessment and the CTI-scores of five products from top-50 per category.

Action uses the CTI scores of products to monitor the progress for this material topic. The inflow and outflow of material determine the circularity score and is calculated according to the CTI framework.

Monitoring and evaluation

Our initial target is to improve the CTI score of five products from the top 50 per product category. This means steadily increasing the percentage of circular products in our assortment. In 2023, we will set new circularity score targets for all categories for 2024.

Remaining targets

Circle Economy is an important stakeholder on circularity. They support our Buying and Quality teams to improve our awareness and implementation of circularity. Circle Economy has contributed by collecting and analysing product data of the top 50 products per category, based on sales volume and weight. This was used in category circularity sessions with the buyers to inform and prioritise circular product interventions on a product level to increase product circularity.

The role of stakeholders

made of 80% recycled plastic

Garden set

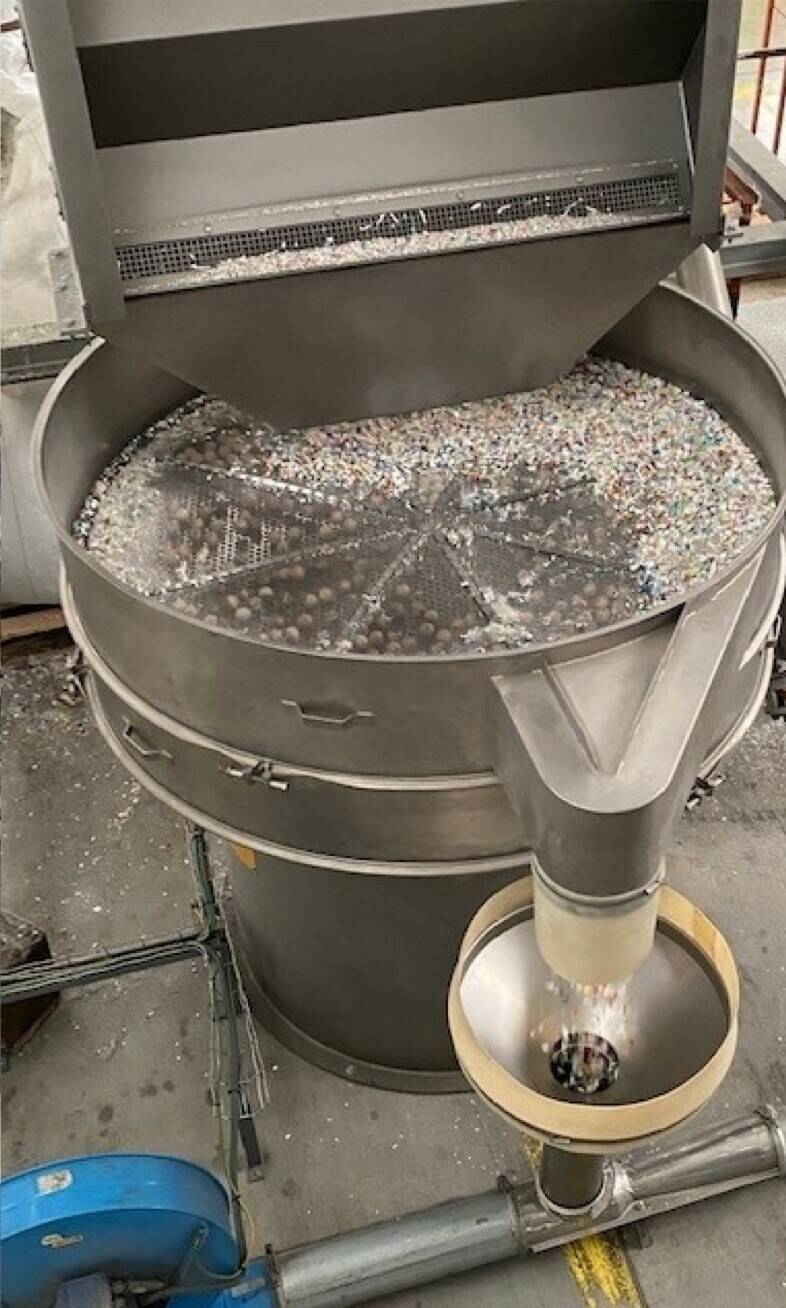

This garden set is produced in Spain and made of 80% recycled plastic. The factory that produces the garden set, has a facility where recycled post consumer plastic is converted into "new" raw material for the production of this set. View the process of the recycled plastic material that is used to manufacture the garden set.

Back to Product

Back to Product

Product circularity

We have embraced the circularity philosophy because we recognise that we cannot continue to rely on finite, non-renewable resources. In this year’s materiality assessment, Product circularity was confirmed as an important material topic. Our progress is measured through the circularity percentage per product category.

Wall of fame

changed to 100% recycled polypropylene

Action shopping bag

changed to 40% recycled aluminium

Marble stone frying pans

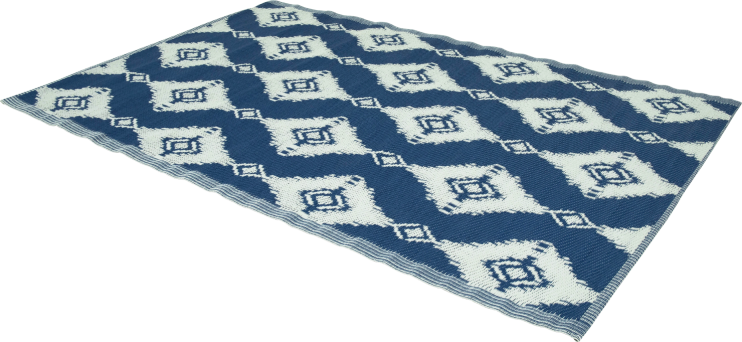

changed to 100% recycled plastic

Outdoor carpet

Management of material topic

The responsibility for product circularity is taken seriously at Action and managed per product category. We look at the three stages of circularity: design, use and end of life. Depending on the type of product functionality, we define which circular improvements to make.

We also have special policies for unsold and damaged goods. Of course, we aim to sell as many of our products to our customers. In the case of seasonal unsold goods, we store them in our DCs for next year. In addition, we move stock from store to store, so we refill stock in one store with the surplus of another store. Items that are not sold despite our efforts or that we no longer wish to sell ourselves are sent back to our DC and sold on to other resellers.

The damaged goods that are returned to our store are carefully selected and categorised into waste or re-sellable products. Re-sellable products can find their way back to our own stores or to other markets. The waste is carefully separated. For example, food, iron, copper, plastic and electronics are collected by organisations that process it into reusable materials. Hazardous materials, such as batteries, are already collected in our stores and processed separately.

Progress made

In 2022, we completed all fourteen circular category baseline assessments and have already improved 10 categories based on the assessment and the CTI-scores of five products from top-50 per category.

Action uses the CTI scores of products to monitor the progress for this material topic. The inflow and outflow of material determine the circularity score and is calculated according to the CTI framework.

Monitoring and evaluation

Our initial target is to improve the CTI score of five products from the top 50 per product category. This means steadily increasing the percentage of circular products in our assortment. In 2023, we will set new circularity score targets for all categories for 2024.

Remaining targets

Circle Economy is an important stakeholder on circularity. They support our Buying and Quality teams to improve our awareness and implementation of circularity. Circle Economy has contributed by collecting and analysing product data of the top 50 products per category, based on sales volume and weight. This was used in category circularity sessions with the buyers to inform and prioritise circular product interventions on a product level to increase product circularity.

The role of stakeholders

made of 80% recycled plastic

Garden set

This garden set is produced in Spain and made of 80% recycled plastic. The factory that produces the garden set, has a facility where recycled post consumer plastic is converted into "new" raw material for the production of this set. View the process of the recycled plastic material that is used to manufacture the garden set.

Back to Product